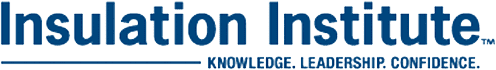

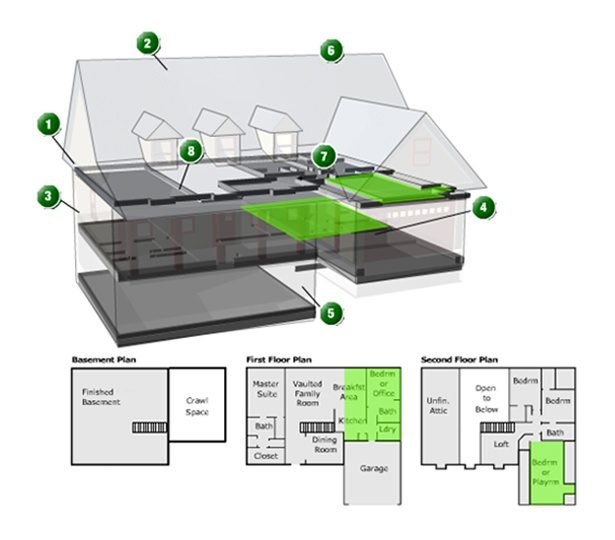

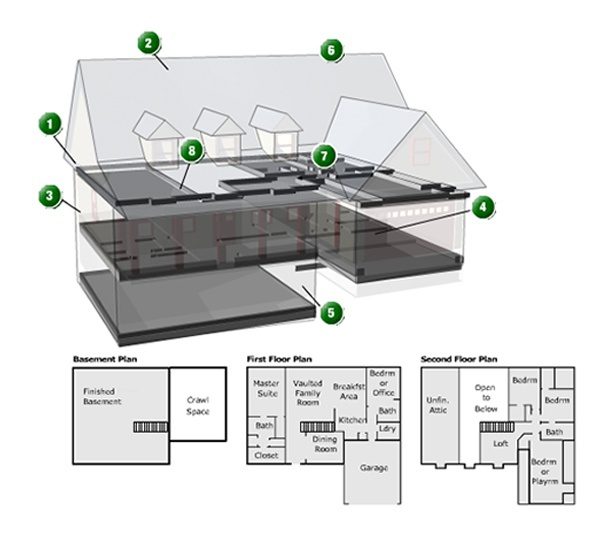

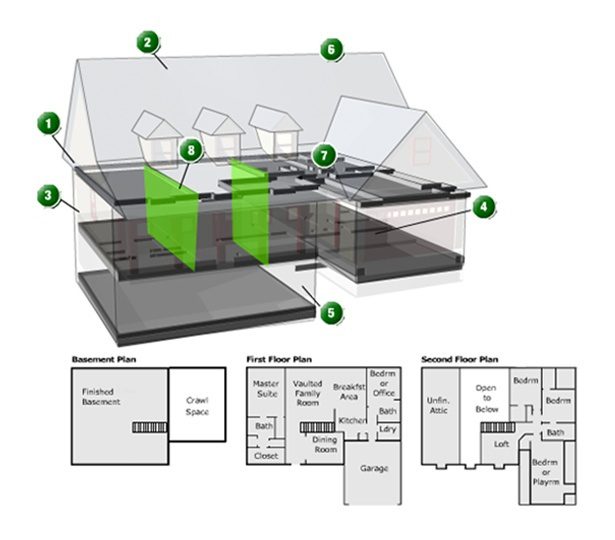

Not sure where exactly to insulate? Probably in more place than you think. In addition to walls and attics, insulation should be installed in ceilings with unheated spaces, basement walls, floors above vented crawl spaces, cathedral ceilings, floors over unheated garages or porches, knee walls, and in between interior walls—especially bathrooms—as well as ceilings and floors. The goal is to create a consistent wrap around the home, a “thermal envelope,” with no penetrations.

But, not every area is easily accessed. Ceilings and attics are always good places to start, both because they are accessible and because more heat escapes through the roof than any other part of the home.

Insulation in attics, walls and beyond

1. Attics and flat ceilings

–+

The most common products for attics and flat ceilings are R-30 and R-38 fiberglass or mineral wool batts. Note that these products are full width – 16″ or 24″ wide. This is to assure that the insulation fills the spaces between the ceiling joists or bottom chords of trusses and also extends above and closes over most wood members. To achieve R-values of R-38 and higher, two layers can be used and their R-value combined. For example, an R-19 batt added to an R-30 will yield an R-49.

Fiberglass or mineral wool loose-fill insulation can also be used. The insulation can be installed to any R-value. However, to achieve the correct R-value it is extremely important that the proper amount and minimum thickness of insulation be installed. Always check the manufacturer’s recommended installation instructions and install the proper amount.

A combination of batts and loose-fill insulation is another alternative. This method is particularly effective in homes with roof trusses or hard-to-reach “nooks and crannies” – places that are prime for energy loss.

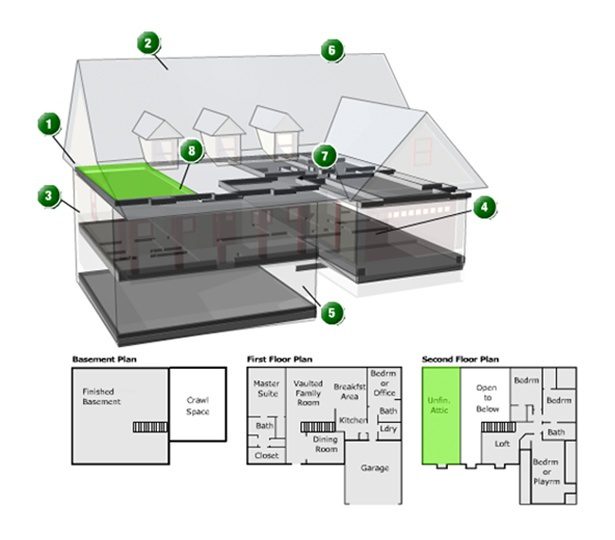

2. Cathedral Ceilings

–+

High-performance batts designed for cathedral ceilings have R-values of either 30 or 38. The R-30 high-performance batts are 8 1/4 ” to 8 1/2 ” thick as opposed to standard R-30 fiberglass batts of 9 1/2 ” to 10″ (Thickness may vary by manufacturer.) R-38 high-performance batts are 10″ to 10 1/4 ” thick as opposed to standard R-38 fiberglass insulation batts of 12″. Because high-performance batts achieve the same R-value as standard insulation – and are not as thick – they need not be compressed to fit the angles and spaces typically found in cathedral ceilings.

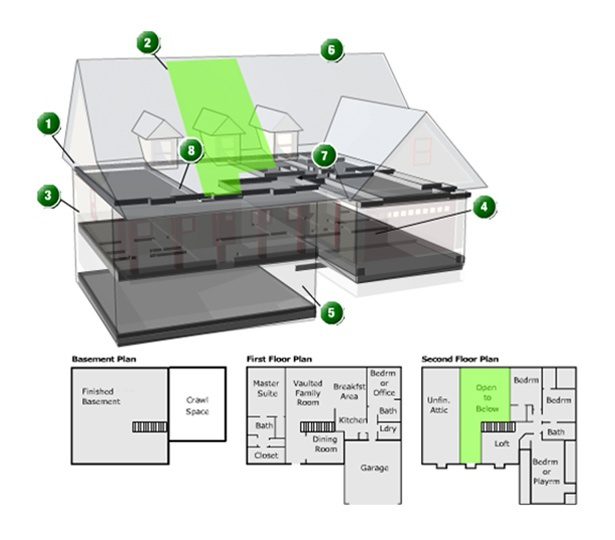

3. Side walls (to the exterior)

–+

Today’s insulation products are manufactured to fit in both 2 x 4 and 2 x 6 construction. Standard sidewall widths of both 15″ and 23″ are available. (16″ and 24″ widths are available for steel stud construction.) In many parts of the country, building codes today call for insulation levels of R-19 or higher in sidewall assemblies. This usually includes the insulation and exterior sheathing.

4. Floors and Crawl Spaces

–+

Some areas that are often overlooked: floors over unheated or open spaces such as garages or porches, floors over unheated basements and the cantilevered portions of floors. Floor insulation can also help with sound transmission, so it can make sense to use it even between two conditioned spaces. Standard batts and high-performance batts can be used under floors.

When insulating floors over unheated basements or crawl spaces, faced products should be used and vapor retarders should face heated areas and be in contact with the subfloor.

Unfaced R-25 or R-19 insulation batts are usually cut into small pieces to fit snugly between the floor joists against sills and band joists

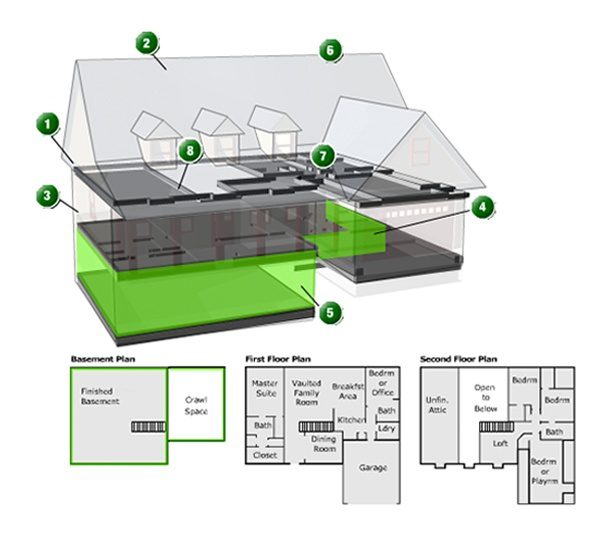

5. Basements

–+

For finished basements, standard or high-performance batts can be used depending on the R-value required. Vapor retarders should face heated areas and be covered as soon as possible.

For insulating foundation walls of heated crawl spaces, use either unfaced insulation where the building code does not require a vapor retarder, or insulation with a special facing recommended for exposed applications. The insulation should be fastened to the sill plate and draped down the wall. The recommended R-value for this application varies by geographic area.

Verify that the walls are dry and do not leak ground moisture before insulated a basement.

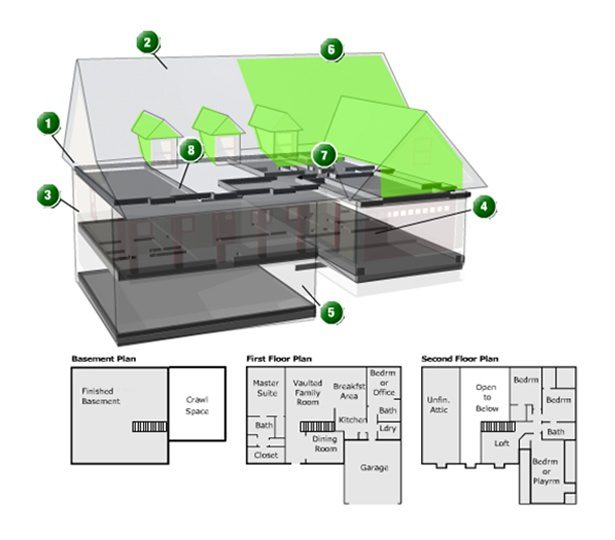

6. Ductwork

–+

Perhaps the easiest area to overlook for insulation in the home is ductwork. Insulation products such as fiberglass duct board, duct wrap and duct liner are used to increase indoor comfort by delivering heated and cooled air from room-to-room at design temperatures, controlling condensation and abating sound such as cross talk heard between two rooms or HVAC equipment noise.

Fiberglass Duct Board

Fiberglass duct board is 1″, 1-1/2″ or 2″ thick rigid boards of insulation manufactured from resin-bonded inorganic glass fibers. This bonding keeps the fibers in place throughout the life of the installation.

Fiberglass Duct Liner

Fiberglass duct liner is a thermal and acoustical insulation applied to the inside of sheet metal ducts. These insulation products have coated or mat-faced airstream surfaces designed to resist damage during installation, in service, and during cleaning.

Fiberglass Duct Wrap

Fiberglass duct wrap is a flexible, resilient blanket which is applied to the exterior of sheet metal ducts. It can be easily cut and fitted to achieve a neat, thermally effective exterior insulation blanket over rectangular, round, oval, or irregularly shaped duct surfaces.

7. Easy to overlook areas

–+

To achieve maximum thermal efficiency, it is important to insulate any space where energy can be lost and comfort can be compromised. The following areas are often overlooked:

- Walls between living spaces and unheated garages, dormer walls, portions of walls above ceilings or adjacent lower sections of split-levels

- Kneewalls of attic spaces finished as living areas

- Sloped walls and ceilings of attic spaces finished as living areas

- Floors over unheated or open spaces such as garages , porches, unconditioned basements or cantilevered floors

- Sidewalls where plumbing fixtures are to be placed must be insulated before the fixtures are installed

- Openings through building sections. Where pipes, wiring, or ductwork penetrate a building section, insulation should be packed tightly into the openings to reduce air infiltration or use caulk to seal the holes

- Junction boxes for wall switches and convenience outlets at outside walls should be insulated between the rear of the box and the sheathing

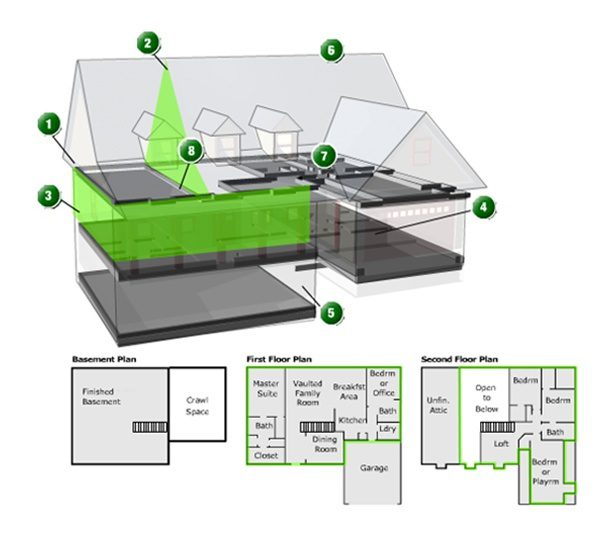

8. Interior Walls

–+

Adding insulation beneath drywall in a typical interior wall can increase sound control and increase the Sound Transmission Class (STC) rating. In most homes, walls between rooms are only marginally effective at blocking noise. By far the easiest and most economical method for controlling noise is to install insulation in the wall cavity.

Acoustic batts, designed to minimize noise, are essentially the same as their corresponding thermal batts, except that they are usually not tested for their R-value. However, fiberglass and mineral wool batts have generally the same noise control properties, so using either acoustic batts or thermal batts will help minimize noise.