We’ve all seen the technique; it is very common in the building industry. A product manufacturer shows how their product can reduce or eliminate the need for other associated products, typically those that comprise some building system. The approach gets customers to think about costs holistically versus piecemeal. This happens in many industries, but given the complexity and systems-design nature of home construction it is very common in the building industry. The problem is that when multiple new assumptions are introduced into cost analyses you really need to look at the fine print to understand if all the assumptions are legitimate.

Details »Insulation Institute Blog

Posts By: Stacy Fitzgerald-Redd

Air Sealing’s Top Hits

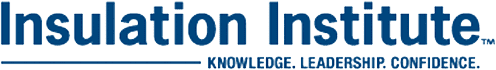

Energy Efficient homes are in high demand among consumers and are a business imperative for builders who want to remain competitive. Air sealing is critical to achieving energy efficiency. But, when it comes to air leaks within a home, all points of entry are not created equal. Big holes in a building enclosure are easy to avoid, identify and fix, but smaller holes have proven to be a big problem. For any building to meet ever more stringent energy efficiency targets, all gaps and openings in a building enclosure should be air sealed. However, with so many possible air leakage points, and limited time/money to devote to air sealing, builders need to focus on getting the most bang for their air sealing buck.

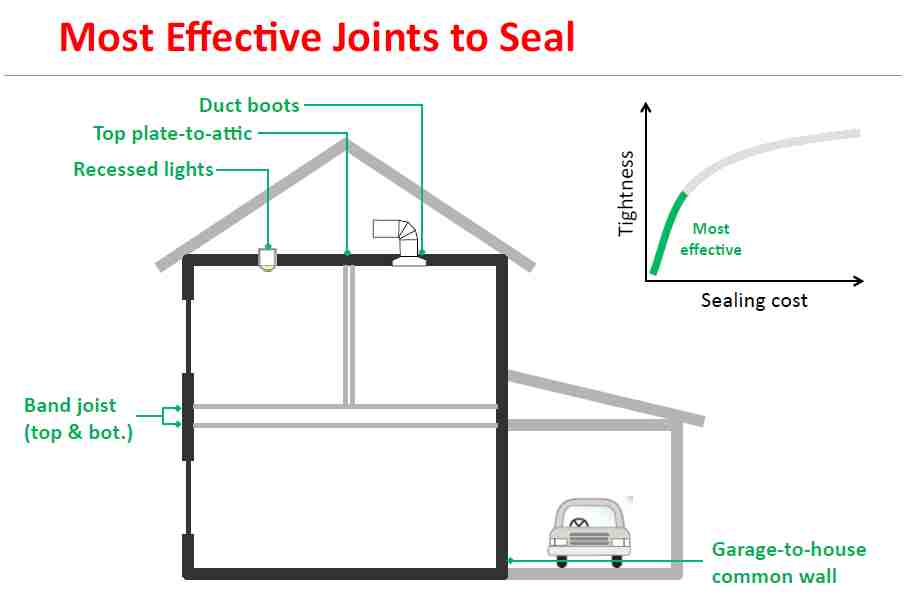

Details »Wall Assembly Including Fiber Glass Insulation Proves Peak Performer in New Study

A new study from Re:Vision Architects draws attention to a common flaw in research of products for the build environment: materials research and product selection typically focus on single-product performance, when very few building assemblies are composed of single products, but rather a combination of products. This simplistic approach led researchers Christopher Lee and Nicole Campion to look instead at the performance of wall assemblies, versus single products. Their study considered five wall assemblies and the results showed that and double stud wall using fiber glass insulation was among the top performing assemblies.

Details »ICC Code Changes Give Builders More Options

In the first of a two-part series for Builder Online, Owens Corning’s Clarke Berdan details the implications for builders (more choices!) following two sets of code changes approved during the April International Code Council Meeting. One new change enables builders to use air permeable (fiber glass) insulation in unvented attics. Previously, the lack of approved air permeable insulation options meant builders had one choice: spray foam insulation. The new proposal will allow for four more options.

Details »“The Plate Escape”: where you’re leaking the most air

In the 1963 film “The Great Escape”, we were rooting for McQueen, Bronson, Attenborough and crew to safely escape the Nazi prison camp. When it comes to air fleeing our homes, our hope is exactly the opposite. Codes and customers are pushing for more energy efficient homes, and that means tighter envelopes. Tighter homes have significant impacts on both moisture management and air quality, but at a more basic level, they are just plain hard to build. A tight home is a result of successfully combining People, Practices and Products (our 3 Ps of air sealing) to deliver the desired result. Executing requires diligence from multiple subs, at many stages of a build, typically employing multiple products, both air barrier materials and sealing accessories. This complexity begs the question: how do I prioritize my focus (and my money) to attack the biggest problems first?

Details »Why Insulation is Crucial for Moisture Management

Moisture is one of the most damaging elements a building can encounter and is the leading cause of construction litigation. In a recent post for Professional Builder Magazine, Johns Mansville Principal Building Scientist J.R. Babineau talks about the role insulation plays in managing moisture in a wall system and why the issue is becoming increasingly important as energy codes become more stringent.

Details »Zero Energy Ready Homes…Using Fiberglass Batts

Back in March, we wrote about the wide array of insulation and air sealing approaches used by homes that meet DOE’s Zero Energy Ready Home (ZERH) specification. Among the approaches that can work is the use of fiberglass batts. Mutual Housing California demonstrated how to use batts to achieve ZERH certification in their Mutual Housing at Spring Lake development in Woodland, California. This 62 unit project was the first multifamily, affordable rental development to receive ZERH recognition. However, getting that performance level with batts requires acknowledging a basic fact: the product can get you the performance, but only if the installation is up to snuff.

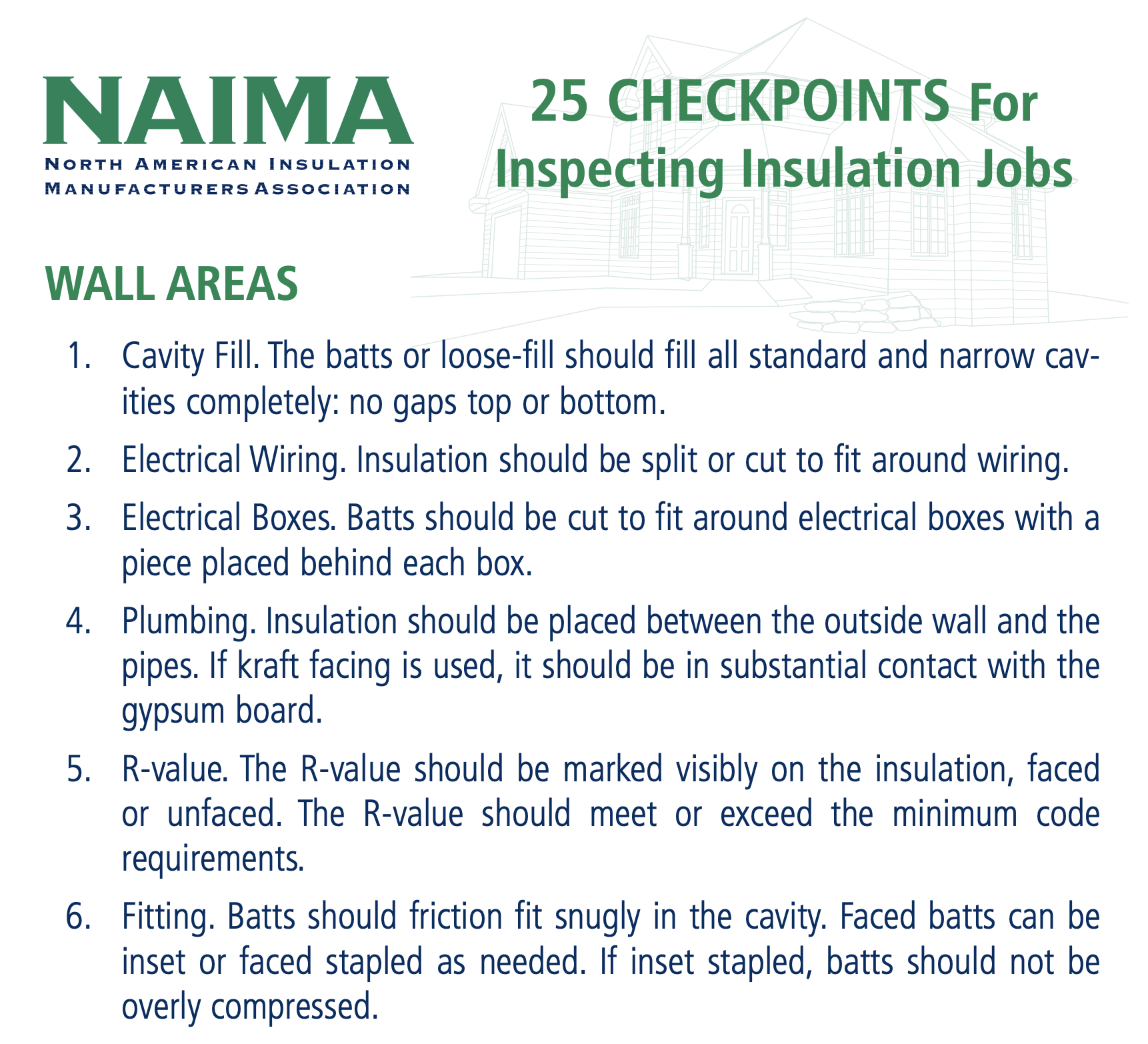

Details »Insulation Installation: You Don’t Get What You Expect, You Get What You Inspect

One of the things that impressed me most as a first-time attendee of the RESNET conference in March of this year was the caliber of the speakers – they all seemed knowledgeable, credible and more often than not, entertaining. I’m a big fan of soundbites, and I usually leave a meeting with a few good ones that I think capture the essence of those subjects most applicable to me. A good one from this year’s conference: “You don’t get what you expect, you get what you inspect.” This is a good message generally, but this really resonated with me when it comes to installation of insulation.

Details »What the “Google Era” Means for Energy Efficient Homes

Over the first half of 2016, The Insulation Institute conducted qualitative research[1] with builders exploring a few areas, including the changing dynamic between home builders and home buyers. The “Google Era” has changed the way homebuyers enter into the buying process and is reshaping their interactions with builders. They are researching more; more about homes, more about building products, just more in general. This leads to new opinions and new questions for builders, including about energy efficient homes. These opinions and questions can be a problem, if not responded to effectively. Our research found that builders can employ three effective techniques when faced with a buyer (or prospective buyer) who has ideas about energy efficient homes that may be a challenge if not properly addressed.

Details »There’s Insulating a Building. And Then There’s REALLY Insulating a Building.

For an insulation inspection during a building inspection, our handy guide – “25 Checkpoints for Inspecting Insulation Jobs” – covers all the bases, and then some. Intended to provide useful guidance on how to improve the quality of the installation of insulation products, the List has been created by our experts here at the Insulation Institute. It tells you what to look for when inspecting insulation in wall areas, as well as ceilings, floors and other areas.

Details »