Transformations taking place in both the home energy efficiency arena and healthcare are coming together in ways that present opportunities for these industries to work collaboratively to improve outcomes for customers. VEIC, a sustainable energy company with a mission to enhance the environmental and societal benefits of clean and efficient energy use for all people, is out with a new Energy-Plus-Health Playbook. The playbook examines a three-tiered approach to targeting unhealthy and substandard existing housing conditions that cause energy burdens and compromise the household health of low- and middle-income customers.

Details »Insulation Institute Blog

One of the best ways to keep informed of building industry trends and learn insights from industry experts is reading blogs and publications. However, sometimes, these sources can leave readers confused about the fundamentals of building science, the performance of building products, and ultimately, share misleading information. Frequently, writers conflate the role of insulation and air sealing, so it’s important to examine the difference.

Details »With nearly one-quarter of new homes carrying a HERS rating, consumers in the energy-efficient home market need to understand why this metric, similar to the miles-per-gallon rating of new cars, is key to evaluating a home’s energy efficiency. To help consumers better understand HERS ratings and the benefits of a HERS-rated home, Residential Energy Services Network (RESNET®) has launched a new consumer website and will conduct a consumer campaign this year to increase awareness.

Details »Green or sustainable construction is estimated to make up one-third of single-family and multifamily home construction, and that number will likely increase to roughly 50 percent by 2022.[1] Such energy-efficient homes are in high demand among buyers because they are less costly to own, more comfortable, and generally command a higher resale value than standard code-built homes.[2] Real estate professionals who are knowledgeable about sustainable or energy-efficient features in homes can be a source of education and information for potential buyers, but their knowledge of such features and their impact varies. A new report from the National Association of Realtors® looks at realtors’ knowledge of sustainability in the industry and provides insights into the extent to which green features appeal to buyers.

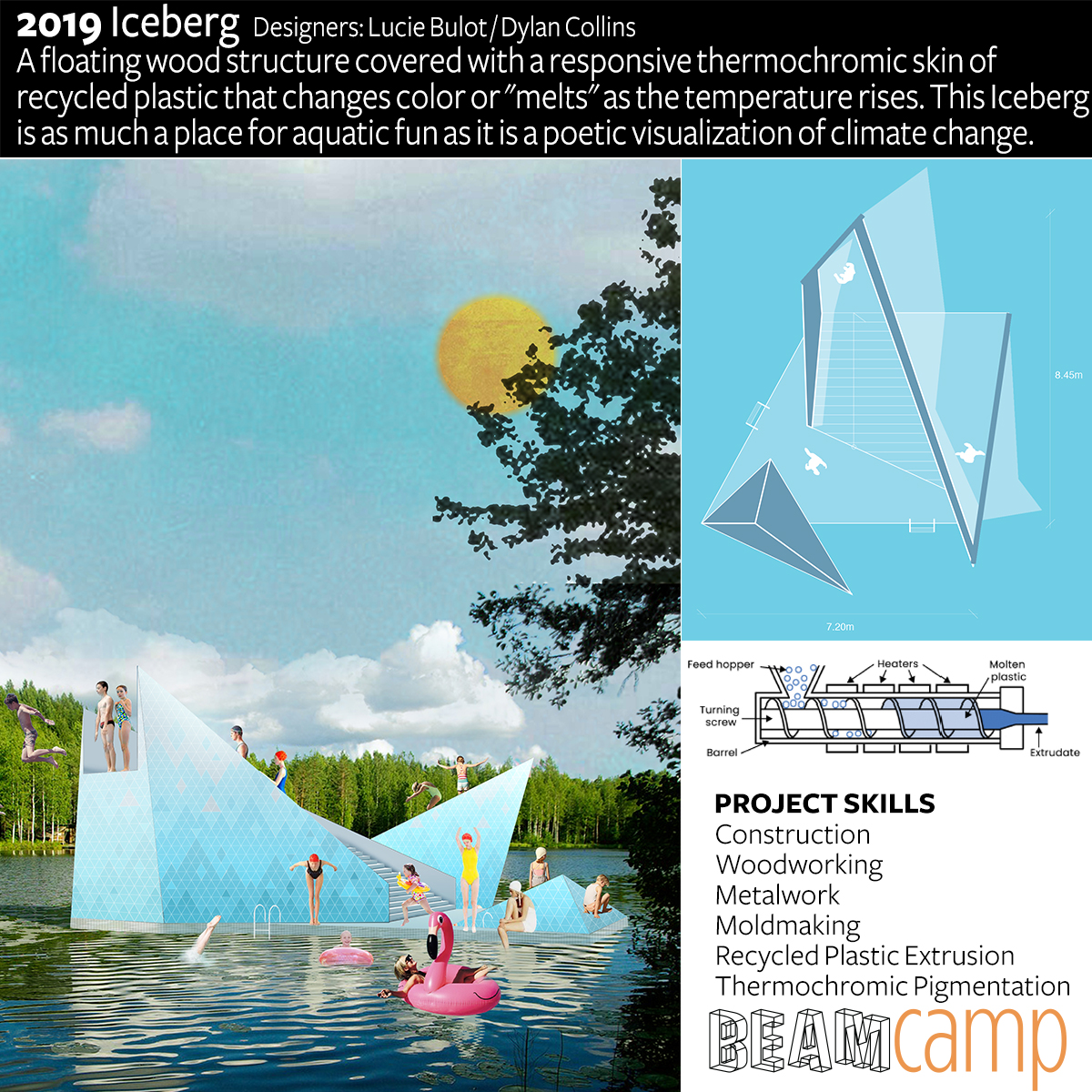

Details »Introducing young people to the construction trades can be a challenge, and many high school students have never thought about a career in the industry. Enter Beam Camp: a novel summer camp that introduces kids to building things with their hands. It’s a simple concept that introduces kids to engineering, construction, and teamwork – and it could plant the seeds for future careers in construction.

Details »When newer editions of the International Energy Conservation Code (IECC) are introduced in states, often there’s a learning curve for home builders, especially when it comes to verification of a home’s air tightness with a blower door test. Some builders are having a tough go of meeting the new requirements. Increasingly, they’re relying on energy efficiency professionals, like HERS raters to help them achieve the target. Insulation Institute spoke with Jonathan Lang, Manager of Training & Certifications for Knauf Insulation who is a BPI Certified Building Analyst, Building Performance Specialist, and ICC Residential Energy Inspector (whew!). We spoke about the challenges builders face in meeting air tightness requirements and why communication and education are so critical to meeting the targets.

Details »While the growing legalization[1] of cannabis in the U.S. may be fueling new industries and is leading to an economic boom in states where it is legal, the use of drugs and alcohol on the job site can have a devastating impact on safety. Drug and alcohol abuse is prevalent among full-time construction

Details »Which is the more cost-effective method of reaching energy code requirements, saving energy or generating it with solar panels on-site? According to a new report, the answer is clear.

Details »Joe “Radio Joe” Hughes of the IAQ Training Institute and IAQ Radio has been training builders and contractors for nearly two decades on indoor air quality issues. Through his popular podcast, trainings, and conferences, he shares insights on building science and the complexities of modern construction, and why indoor air quality is becoming more precarious. Insulation Institute recently spoke with Hughes about why the approach to indoor air quality in new construction must change.

Details »Fixr.com recently published its 2019 Energy-Efficient Home Design Trends Report. The study’s authors interviewed 25 experts in the home design industry to peg upcoming trends in energy-efficient home features, design, and building trends. These experts have a pulse on what consumers want in design but are also savvy about energy efficiency and its importance to home buyers.

Details »