As the year ends, we thought our subscribers would be interested in our top five blog posts of 2017. While we write about a wide range of topics related to residential building, our blogs about proper installation and air sealing were among the most popular. If you’ve missed any of these, perhaps the holiday slowdown will provide a minute or two to read them.

Details »Insulation Institute Blog

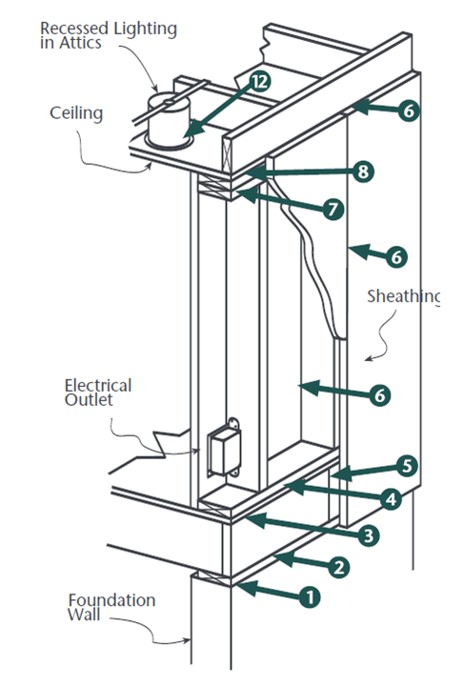

Getting high performance walls relies on proper air sealing before installing insulation, regardless of the insulation used. Air sealing is the most critical component of meeting the blower door testing requirement of the Residential International Energy Efficiency Code (IECC) 2012/15. To meet the 3 ACH50 target builders, contractors, and designers must develop an air sealing strategy. This can’t be done without understanding where homes typically leak air to prevent and/or address the top air sealing trouble spots.

Details »As we reported earlier this year, 36 states currently use a version of the residential energy code equivalent to the 2009 International Energy Conservation Code (IECC) specification or lower. As states work to adopt and implement more recent versions of the IECC (2012 or 2015), some builders may find it challenging to meet the blower door testing requirements of newer energy efficiency codes. Moreover, doing this cost- effectively is a top-of-mind concern. But, builders can leverage existing relationships with manufacturer partners and an energy consultant or HERS rater to keep costs in check and meet airtightness requirements.

Ron Davis, owner of Ron Davis Custom Homes takes pride in the craftsmanship of the luxury homes his company builds in and around Dallas, TX. The company has a reputation for quality and is committed to energy-efficient building, constructing HERS-rated and Energy Star homes. By working with a top energy consultant and a national insulation manufacturer, Davis developed a successful, repeatable strategy for building airtight, High-performance Homes. The approach allows this high-end builder to meet stricter airtightness levels without breaking the bank.

Details »Since 2013 the U.S. Department of Energy’s (DOE) Housing Innovation Awards has recognized the top builders of zero energy ready homes. Housing Innovation award winners represent the top one percent of builders across the country who meet the most rigorous specifications for High-performance Homes. Among this year’s 24 winners is production builder Charles Thomas Homes.

Founded in 2009, Charles Thomas Homes constructs High-performance Homes that typically command a higher price than competing builders, but also deliver on energy efficiency and comfort, which is important in frosty climate zone 5. Part of the company’s winning approach to constructing energy-efficient homes includes blown fiberglass insulation in the attic and walls, demonstrating that high-performance doesn’t have to mean high price.

Details »Residential Energy Services Network (RESNET) recently reached a significant milestone: 2 million Home Energy Rating System (HERS)-scored homes. This miles-per-gallon equivalent score assigned to estimate the energy efficiency of a home has rapidly gained market acceptance since its inception in 2006, and as energy efficient building becomes mainstream, the popularity of HERS ratings continues to expand rapidly. Today, 22 percent of new homes are HERS-rated[1], and that number will continue to grow, particularly as states adopt the energy ratings index (ERI) as an energy code compliance option.

Details »The 2017 Atlantic Hurricane season has been the seventh most active in history. [1] In a year that’s seen widespread home damage and displacement of homeowners as the result of extreme weather events there’s some positive news to report. According to a Wall Street Journal article, homes built in Florida following the passage of more stringent building codes fared better during Hurricane Irma than those built previously. But with more frequent occurrences of hurricanes and damaging storms, should more stringent building codes be the sole defense in limiting property damage and homeowner displacement?

Details »During last month’s Insulation Contractors Association of America Convention, Burgess Construction Consultants reported the results of a recent survey it conducted with more than 100 of the nation’s top production builders. The company sought to identify ways that builders, HERS raters and insulation contractors could work more collaboratively to achieve superior home energy performance.

Details »Contributed by Modernize

There’s all kinds of potential for smarthome devices, from better security to an easier way to turn off the lights. But one of the greatest benefits—at least, environmentally-speaking—is the ability to provide more insight into a home’s energy consumption. Stand-alone smartphone apps can offer suggestions for how to incorporate greener habits into a homeowner’s daily routine. And then there are the device-centric apps, which integrate with existing smart products in the home—such as the utility meter or thermostat—to give homeowners a better readout of their energy use and saving.

Details »When properly installed, housewrap can be the workhorse of a home’s exterior envelope, as a weather-resistive barrier that performs as the buildings shell, repelling water while also allowing water vapor to pass to the outside of the structure. But, like everything else in construction, it only works well if properly installed. Rex Nelson of Correct Housewrap Installation estimates that 90 percent of housewrap installations are bad, which he says is not only avoidable, but potentially very damaging to the home’s exterior. Nelson says that contractors should understand what the product is intended to do and be trained on properly installing it, which will help improve housewrap jobs and building durability in the long run.

Details »