Energy efficiency is indisputably essential to addressing global climate change. At the forefront of organizations promoting strategies to tackle the climate crisis is the Natural Resources Defense Council (NRDC). Insulation Institute spoke with David Goldstein, Co-Director of Climate and Energy at NRDC, about how the building sector in America can more aggressively pursue a comprehensive energy efficiency initiative to address climate change. Goldstein is a heavy hitter in the energy efficiency arena, having worked since the 1970s on energy efficiency and energy policy (and also founded Residential Energy Services Network). Goldstein offers the following four-point blueprint for achieving an active decade of progress on climate goals.

Details »Insulation Institute Blog

Posts Categorized: Energy Efficiency

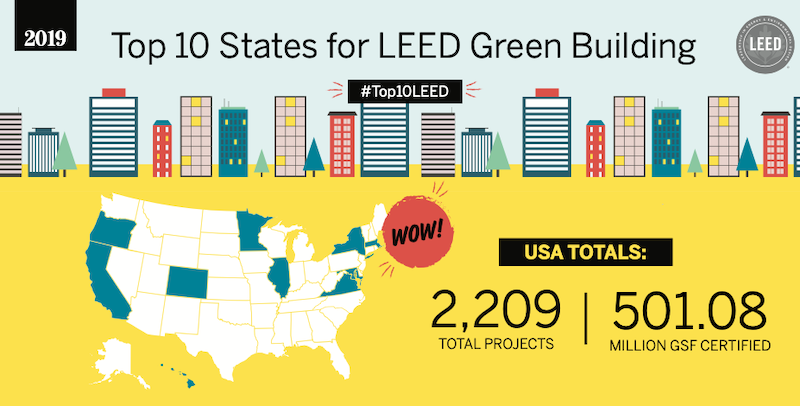

The Top 10 States for LEED Green Building

Leadership in Energy and Environmental Design (LEED) is the most widely used green building rating system in the world, and the number of LEED-certified buildings in the United States continues to grow. The U.S. Green Building Council (USGBC) recently released the top 10 states for LEED Green building in 2019, a year in which the total number of certified projects reached 1,181.

Details »Number of HERS-Rated Homes Grows

The number of HERS-related homes in the United States continues to expand, according to new data released by Residential Energy Services Network (RESNET). In 2019 a total of 241,909 homes in the United States were HERS-rated compared with 236,116 in 2018. That is an increase of 5,793 homes in one year. To date, 2.7 million homes have been HERS-rated.

Details »Home Sellers Must Prove Energy Efficiency

Home Sellers Must Prove Energy Efficiency

As we reported in last week’s blog post, “Five Promising Developments for Decarbonization,” a growing number of state and local governments are targeting building emissions to reduce their carbon footprint. This push for decarbonization will only accelerate. In the move toward decarbonization, targeting buildings – both commercial and residential – is low-hanging fruit. It’s not just new construction, but existing construction as well, with home sellers in one jurisdiction now required to measure their home’s energy efficiency before putting it on the market.

Details »5 Promising Developments for Decarbonization

As a new decade begins, there are promising developments on the horizon for building decarbonization and greenhouse gas (GHG) emission reductions in residential and commercial construction. While federal support for decarbonization to address climate impacts is at a standstill, non-governmental organizations, state and local governments, and industry are all focused on sustainability and building decarbonization actions that may ultimately lead to real progress. Here are five promising developments for decarbonization that have the potential to shape an active decade of progress.

Details »Our Top 10 Blog Posts of 2019

Like last year, some of our best-performing blog posts focused on air sealing and proper installation and application of fiberglass and mineral wool insulation, which is no surprise, since we’re the Insulation Institute. However, other topics like energy efficiency design trends and the prioritization of energy efficiency over energy generation ranked highly as well.

Details »The Housing Guy Talks Zero Energy’s Expansion

In the past three months, Sam Rashkin, chief architect of the U.S. Department of Energy’s Building Technologies Office, has been traveling non-stop, speaking at meetings and conferences about the expansion of zero energy buildings in the United States. While accustomed to an exacting traveling and speaking schedule, the demands on his time likely accelerated with word that Rashkin will retire from the DOE and his role as chief housing-efficiency advocate at the end of the year. Insulation Institute recently caught up with Rashkin for an assessment on zero energy building today and where it’s headed in the future.

Details »Energy Efficiency Workforce Grows to 2.3 Million

E4TheFuture’s recently released 2019 report, “Energy Efficiency Jobs in America,” demonstrates the impressive growth of the energy efficiency workforce, which now numbers more than 2.3 million people. The annual report is based on data from the U.S. Bureau of Labor Statistics and is a comprehensive survey of thousands of businesses, using a methodology developed for the U.S. Department of Energy.

Details »Bentley’s 4 Rules for High-Performance Homes

Jeff Bentley is a fifth-generation home builder who’s built more than 4,000 houses and sold more than 2,000 homes in more than 45 years in residential construction. He’s also a HERS rater, LEED Green Builder and REALTOR® whose counsel on energy-efficient home building is highly sought after. Insulation Institute reached out to Bentley to find out what practices can help builders meet more stringent energy efficiency code requirements and dramatically improve the way homes are built in America. Here are Bentley’s four rules for High-performance Homes.

Details »A Model for the Net Zero Built Environment

New York State Energy Research and Development Authority (NYSERDA) has some of the most advanced policies and programs in the country to support a net zero built environment for existing and new construction homes. Other states would do well to follow their lead.

Details »