We at Insulation Institute spend a good deal of our time talking up the benefits of using fiberglass and mineral wool insulation. As much of the content of our blog is geared toward new residential construction, we value connecting with builders who use these products to achieve high-performance new home construction. So, we were thrilled to catch up with Matt Risinger, a Texas home builder and building science enthusiast (and a rock star) who specializes in high-performance, architect-driven home building during the International Builders Show. We’ve heard Matt speak at the International Builders Show in the past and we know his time is a valuable commodity, so we only asked him one question during our brief chat. His answer didn’t disappoint.

Details »Insulation Institute Blog

Posts Categorized: Installation

3 Common Problems Found in New Home Inspections

Home Builders take pride in the quality construction and workmanship of new homes. But even the best builder will occasionally be challenged with flaws in new construction that must be corrected. The complexity of new home construction, buyers’ lack of understanding about new home warranties, and internet savvy consumers raise the stakes for new home purchases and argue for independent home inspections.

Insulation Institute spoke with Frank Lesh, past president of the American Society of Home Inspectors (ASHI) and Mike Chamberlain, owner of MC2 Home Inspections, a certified national home inspector. We discussed the prevalence of inspections for new homes, the three most common issues Chamberlain has encountered during those inspections, and what builders can do to ensure consistent quality construction.

Details »Our Insulation Field Trip

The Insulation Institute is committed to addressing and educating the market on quality installation, conducting training sessions and developing an extensive guide on how to get Grade I installation. Since we represent the insulation industry, we like to get out in the field from time-to-time and see how the products our members manufacture are installed.

So, when we had an opportunity to visit two Maryland homes currently under construction just after the insulation had been installed we jumped at the chance.

Details »Free Grade I Training Coming to Four States

According to U.S. Department of Energy 20 percent home’s energy is wasted because the home is under insulated and improperly air sealed.[1] For builders, this can wreak havoc on productivity, resulting in call backs, jeopardizing code compliance, reducing HERS scores, and resulting in homes that are less energy efficient and comfortable for consumers.

Details »70 Seconds on Why Quality Installs Matter

The housing industry is changing, and quality insulation installation matter more than ever before. Poor quality insulation installation can reduce energy efficiency, lower a home’s HERS score, prevent qualification for certification and incentive programs even endanger code compliance. In this new video, Insulation Institute lays out the business case for builders on quality insulation installation.

What is “Proper” Insulation Installation?

Even the title of this blog adds confusion to a subject that, on the surface, doesn’t seem like it should be that complex. To say there is “proper” installation implies there is also “improper,” in other words just plain wrong. However, some think the assessment of insulation installation quality is in fact much more nuanced than that. Others prefer the more black and white approach. In the face of differences of opinion, where would most in the building industry turn for the final word? To the building code, of course. However, code language may only add to the ambiguity around this subject, and inconsistent code enforcement certainly does. In this blog, we explore the different definitions and terminology related to insulation installation, what code says about it (and what it doesn’t) and why all this matters for home construction, whether it’s code built homes or those meeting more stringent high performance targets.

Details »Training the Trades to Get the Grade

Providence Homes has built more than 1,000 certified Energy Star homes – getting RESNET Grade One, a requirement of Energy Star Home Certification, using fiber glass batt insulation in each home. How does Providence do it, again and again when others say it’s difficult to achieve? One word: training.

Details »Do Quality Insulation Installations Cost More?

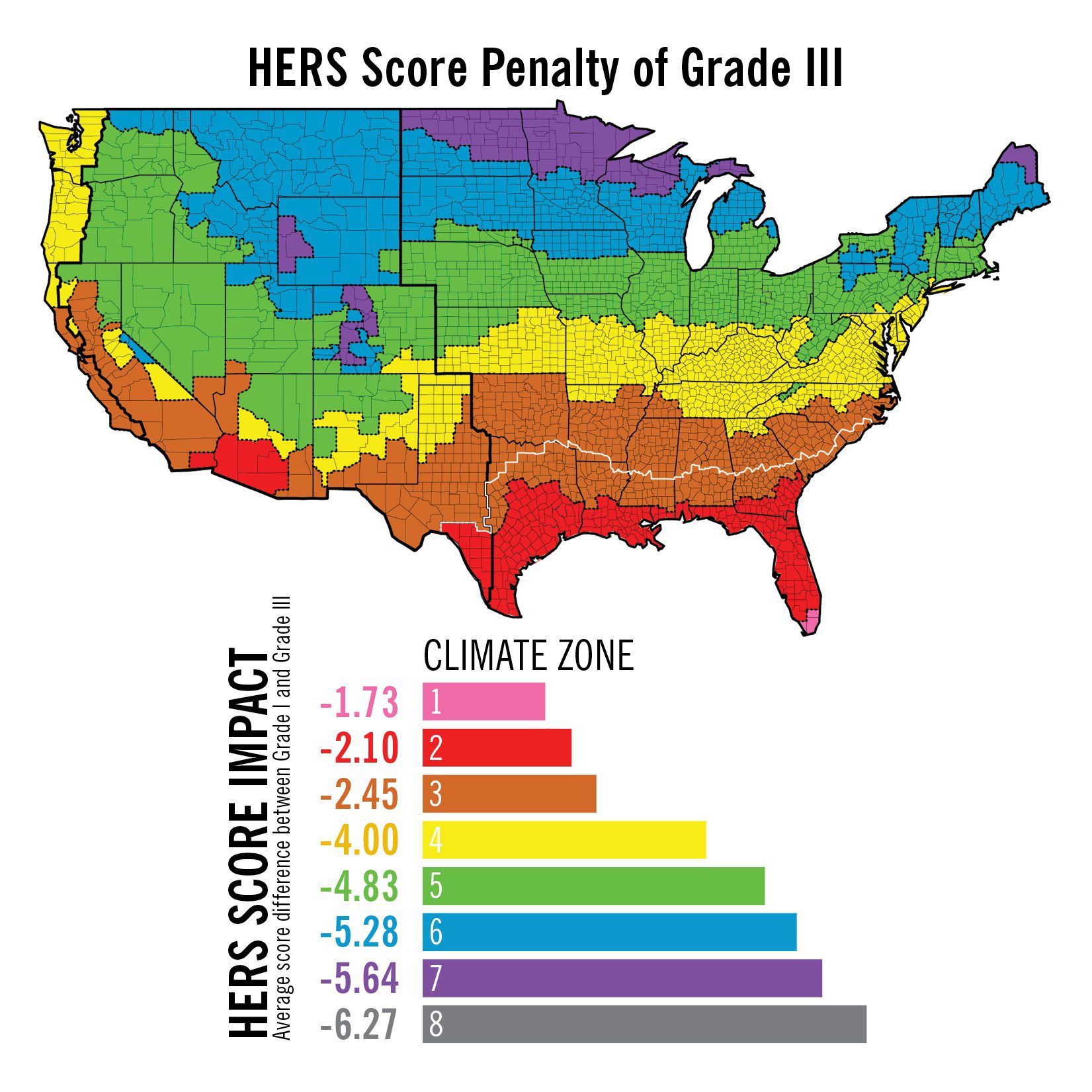

We talk a lot about the importance of quality insulation installation, especially for batts. If the home is getting a HERS rating, Grade III installation means 5% of your insulated area is modeled as uninsulated. For those in California, failing to meet their definition of quality, a Quality Insulation Installation (QII), means wall cavity R-value is discounted 30% when modeled to determine energy code compliance. For Energy Star or DOE Zero Energy Ready homes it’s simple: get Grade I or you can’t be certified[1]. So, there appears to be market value for quality installation, but does that actually manifest itself in installer compensation? If so, how much is it worth?

Details »Fast, Good and Cheap: Enemies of Quality Installation

In the past three years working within the insulation industry I’ve had a many conversations with builders, contractors and our manufacturer members about getting Grade 1 installation using fiber glass batt insulation. Three conversations in particular stick out in my mind as both insightful and accurate: two separate conversations with The Green Building Curmudgeon, Carl Seville, and one with Toler Insulating owner Wayne Toler. Each conversation left me with this: when it comes to quality installation of fiber glass batts, you can’t get fast, good and cheap. So, you have to pick two. Or do you?

Details »