We talk a lot about the importance of quality insulation installation, especially for batts. If the home is getting a HERS rating, Grade III installation means 5% of your insulated area is modeled as uninsulated. For those in California, failing to meet their definition of quality, a Quality Insulation Installation (QII), means wall cavity R-value is discounted 30% when modeled to determine energy code compliance. For Energy Star or DOE Zero Energy Ready homes it’s simple: get Grade I or you can’t be certified[1]. So, there appears to be market value for quality installation, but does that actually manifest itself in installer compensation? If so, how much is it worth?

Details »Insulation Institute Blog

Posts Categorized: Insulation

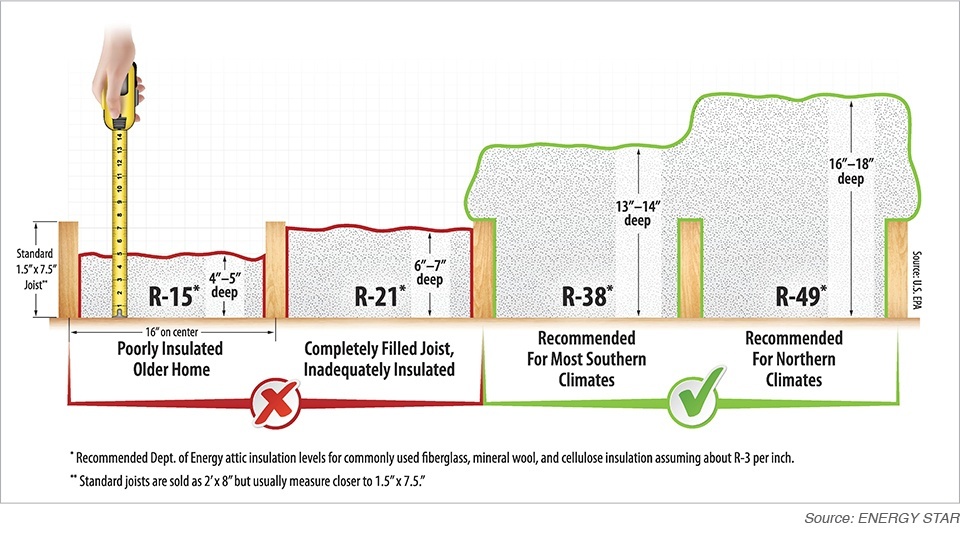

What’s the ROI of Attic Insulation?

As fall approaches it’s time to consider options to weatherize your home. This means making improvements that can help improve comfort and lower energy bills, in the winter months and beyond. For homeowners trying to prioritize their home improvement dollars, and time, the question of what to focus on first often comes up. We’re going to make the case for attic insulation, as new data has come to light regarding its benefits.

Details »“Trades may grumble but customers are lining up”

Addison Homes, a green builder in Greenville, South Carolina, certainly didn’t set out to cause trade partners to grumble, murmur or gripe. They set out to build DOE certified Zero Energy Ready Homes (ZERH) to provide their customers with the energy savings, comfort and indoor air quality such homes deliver. To do that, Addison Homes had to get local trades on board by doing things a bit differently. In doing so, they provided award-winning homes that customers rave about. They even show off the energy-efficient features included in the home (the homeowners in their winning Cobbler Lane project show their guests the pristine conditioned crawlspace…seriously).

Details »Lab Test vs. Eye Test: Slumping and Settling

Over the years, there has been significant discussion about batt insulation slumping and loose fill insulation settling. Manufacturers often discount these claims as inaccurate or the result of rumors spread by competitors. They do this because they have test data they believe proves these defects are not real issues. But the perspective of builders, HERS raters, insulation contractors and other boots on the ground is driven by what they see in the field, and that includes settled loose fill and slumped batts. How do we reconcile the lab test with the eye test?

Details »How “Total Cost” Sales Techniques Can Mislead

We’ve all seen the technique; it is very common in the building industry. A product manufacturer shows how their product can reduce or eliminate the need for other associated products, typically those that comprise some building system. The approach gets customers to think about costs holistically versus piecemeal. This happens in many industries, but given the complexity and systems-design nature of home construction it is very common in the building industry. The problem is that when multiple new assumptions are introduced into cost analyses you really need to look at the fine print to understand if all the assumptions are legitimate.

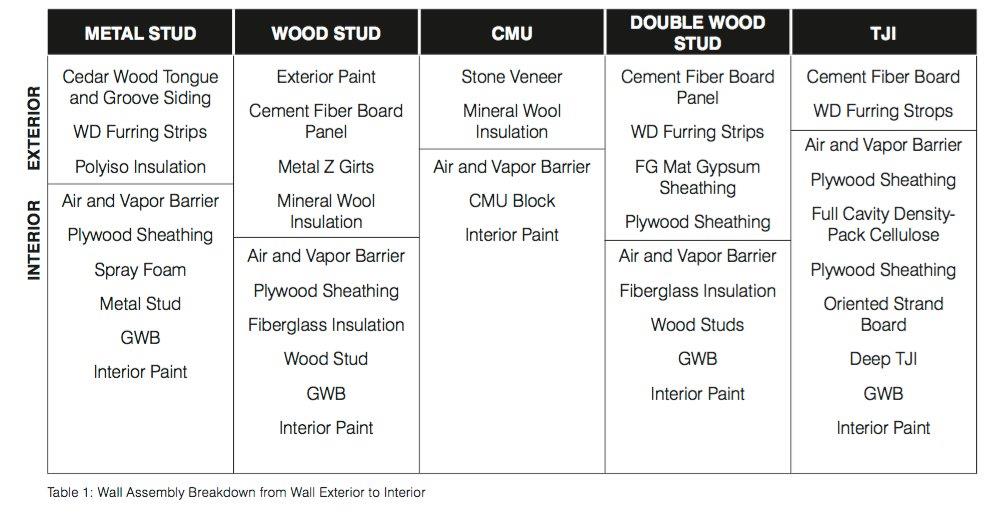

Details »Wall Assembly Including Fiber Glass Insulation Proves Peak Performer in New Study

A new study from Re:Vision Architects draws attention to a common flaw in research of products for the build environment: materials research and product selection typically focus on single-product performance, when very few building assemblies are composed of single products, but rather a combination of products. This simplistic approach led researchers Christopher Lee and Nicole Campion to look instead at the performance of wall assemblies, versus single products. Their study considered five wall assemblies and the results showed that and double stud wall using fiber glass insulation was among the top performing assemblies.

Details »“The Plate Escape”: where you’re leaking the most air

In the 1963 film “The Great Escape”, we were rooting for McQueen, Bronson, Attenborough and crew to safely escape the Nazi prison camp. When it comes to air fleeing our homes, our hope is exactly the opposite. Codes and customers are pushing for more energy efficient homes, and that means tighter envelopes. Tighter homes have significant impacts on both moisture management and air quality, but at a more basic level, they are just plain hard to build. A tight home is a result of successfully combining People, Practices and Products (our 3 Ps of air sealing) to deliver the desired result. Executing requires diligence from multiple subs, at many stages of a build, typically employing multiple products, both air barrier materials and sealing accessories. This complexity begs the question: how do I prioritize my focus (and my money) to attack the biggest problems first?

Details »Why Insulation is Crucial for Moisture Management

Moisture is one of the most damaging elements a building can encounter and is the leading cause of construction litigation. In a recent post for Professional Builder Magazine, Johns Mansville Principal Building Scientist J.R. Babineau talks about the role insulation plays in managing moisture in a wall system and why the issue is becoming increasingly important as energy codes become more stringent.

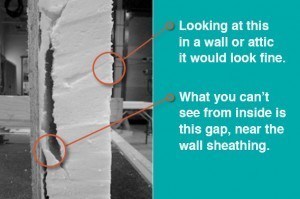

Details »Insulation Installation: You Don’t Get What You Expect, You Get What You Inspect

One of the things that impressed me most as a first-time attendee of the RESNET conference in March of this year was the caliber of the speakers – they all seemed knowledgeable, credible and more often than not, entertaining. I’m a big fan of soundbites, and I usually leave a meeting with a few good ones that I think capture the essence of those subjects most applicable to me. A good one from this year’s conference: “You don’t get what you expect, you get what you inspect.” This is a good message generally, but this really resonated with me when it comes to installation of insulation.

Details »There’s Insulating a Building. And Then There’s REALLY Insulating a Building.

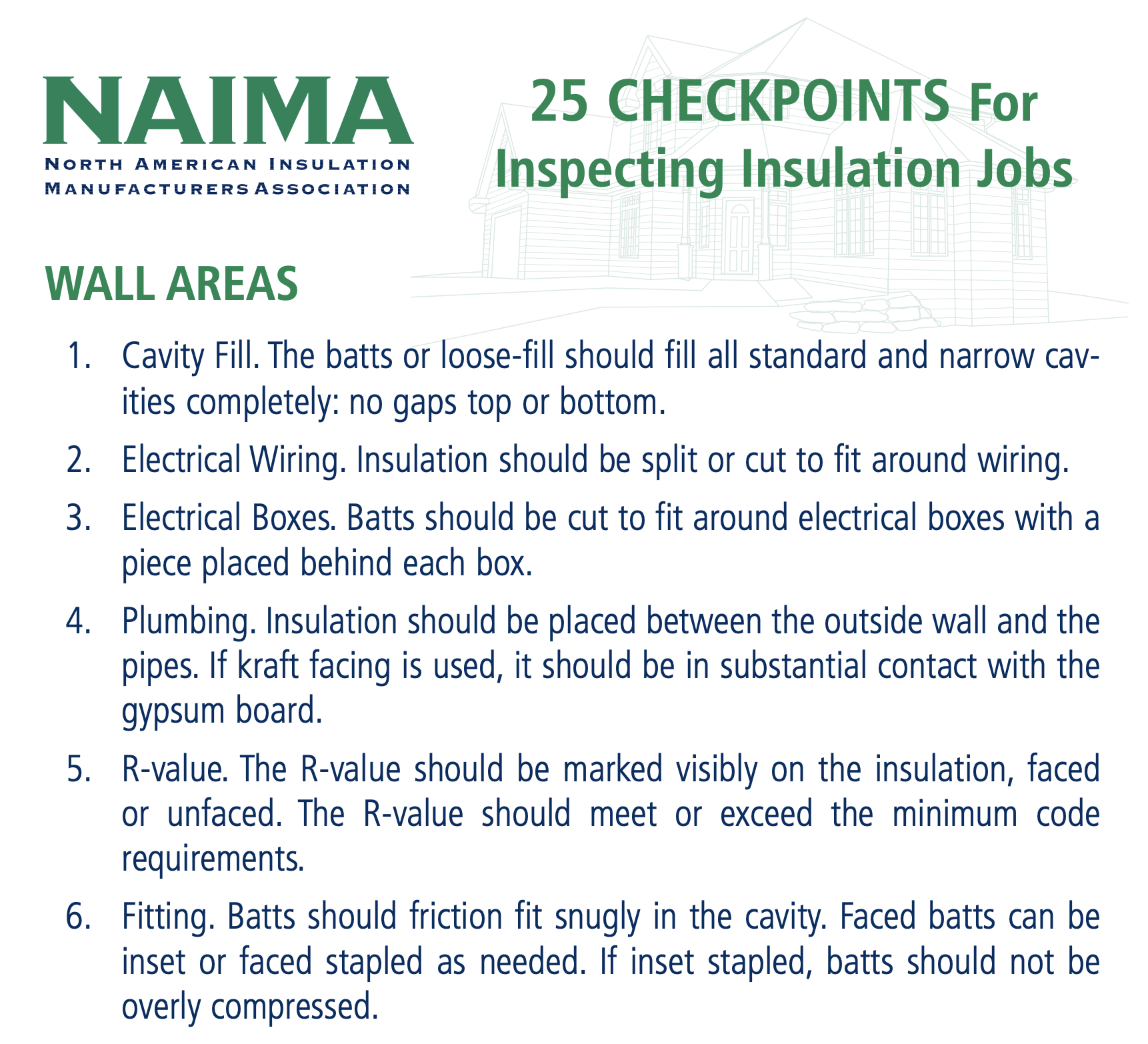

For an insulation inspection during a building inspection, our handy guide – “25 Checkpoints for Inspecting Insulation Jobs” – covers all the bases, and then some. Intended to provide useful guidance on how to improve the quality of the installation of insulation products, the List has been created by our experts here at the Insulation Institute. It tells you what to look for when inspecting insulation in wall areas, as well as ceilings, floors and other areas.

Details »