A vapor retarder is defined as a material or system that adequately retards the transmission of water vapor under specific conditions. Building occupants, certain appliances, plants, and plumbing equipment generate moisture that is carried in the air as vapor.

Moisture control through limiting water vapor movement in buildings is essential. A vapor retarder helps prevent water vapor from moving into building assemblies, like walls, where it can condense into liquid water within the structure. Liquid water can accumulate inside exterior walls and in roof and crawl spaces. If enough water is present, rot and decay can cause significant damage. The kraft facing on insulation with an asphalt coating serves as a vapor retarder. The vapor retarder can reduce the likelihood of condensation within building walls, floors, and ceilings.

Where should vapor retarders be installed?

In areas where the climate is cold in the winter, the vapor retarder should be installed on the inner side of the wall near the warm interior space — or on the warm side in winter. In humid climates or areas where there is extensive use of air-conditioning, if a vapor retarder is required, it should be installed on the exterior side of the wall. A vapor retarder should not be required in climate zones 1, 2, and 3.

Types of Vapor Retarders

The table below shows the perm rating of some common building materials that are consistent with the ASHRAE Handbook of Fundamentals and other industry sources.

Vapor Retarders and Perm Ratings

| Vapor Retarder | Perm Rating |

|---|---|

| Insulation Facing, Kraft | 1.0 |

| 1/4” Plywood (douglas fir, exterior glue) | 0.7 |

| Insulation Facing, Foil Kraft, Laminate | 0.5 |

| 0.003” Vapor Retarder Latex Paint | 0.45 |

| 0.002” Polyethylene | 0.16 |

| 0.004” Polyethylene | 0.08 |

| 0.0006” Polyethylene | 0.06 |

| 0.00035” Aluminum Foil | 0.05 |

| 0.001” Aluminum Foil | 0.01 |

Not Vapor Retarders and Perm Ratings

| 3/8” Gypsum Wall Board (plain) | 50 |

| 4” Unfaced Mineral Wool | 30 |

| 0.002” Latex Paint (typical) | 5.5 to 8.6 |

| 4.4 lb/100ft2 Asphalt Saturated Sheathing Paper | 3.3 |

| 1/4” Plywood (douglas fir, interior glue) | 1.9 |

When is a Vapor Retarder Required?

The latest research on moisture performance of walls and vapor retarders has significantly changed the vapor retarder requirements in the building codes. The most current edition of the International Residential Code (IRC) and International Building Code (IBC) are often acceptable and have the best guidance. Consult your local Authority Having Jurisdiction (AHJ) to determine the vapor retarder requirements for your project.

Vapor retarder requirements in the 2021 and newer editions of the International Code Council (ICC) building codes, are summarized as follows:

- The IRC defines vapor retarders as Class I, II or III based on how permeable they are to water vapor. The lower the permeability, the less water vapor that will pass through the vapor retarder.

- Class I – Very low permeability vapor retarders – rated at 0.1 perms or less. Sheet polyethylene (visqueen) or unperforated aluminum foil (FSK) are Class I vapor retarders.

- Class II – Low permeability vapor retarders – rated greater than 0.1 perms and less than or equal to 1.0 perms. The kraft facing on batts qualify as a Class II vapor retarder.

- Class III – Medium permeability vapor retarders – rated greater than 1.0 perms and less than or equal to 10 perms. Latex or enamel paint qualify as Class III vapor retarders.

The allowable class of vapor retarder by climate zone is listed in the table below, which is from the 2024 IRC:

| Climate Zones | Vapor Retarder Class | ||

|---|---|---|---|

| Class Ia | Class IIa | Class III | |

| 1,2 | Not permitted | Not permitted | Permitted |

| 3, 4 (except Marine 4) | Not permitted | Permitted | Permitted |

| Marine 4, 5, 6, 7, 8 | Permittedb,c | Permittedc | See Table R702.7(3) |

a. A responsive vapor retarder is allowed on the interior side of frame walls in any climate zone.

b. In frame walls, the use of a Class I vapor retarder that is not a responsive vapor retarder on the interior side with a Class I vapor retarder on the exterior side requires an approved design.

c. Where a Class I or II vapor retarder is used in combination with foam plastic insulated sheathing or insulated siding installed as continuous insulation on the exterior side of frame walls, the continuous insulation must comply with Table R702.7(4) and the Class I or II vapor retarder shall be a responsive vapor retarder.

Climate zones for Class III Vapor Retarders

Class III vapor retarders can be used on the interior side of the wall in the following climate zones in any of the conditions outlined.

| Climate Zones | Construction (Table R702.7(3) in the 2021 and 2024 IRC) |

|---|---|

| Marine 4 | Vented cladding over wood structural panels Vented cladding over fiberboard Vented cladding* over gypsum Continuous insulation with R-value ≥ 2.5 over 2×4 wall Continuous insulation with R-value ≥ 3.75 over 2×6 wall |

| 5 | Vented cladding over wood structural panels Vented cladding* over fiberboard Vented cladding* over gypsum Continuous insulation with R-value ≥ 5 over 2×4 wall Continuous insulation with R-value ≥ 7.5 over 2×6 wall |

| 6 | Vented cladding* over fiberboard Vented cladding* over gypsum Continuous insulation with R-value ≥ 7.5 over 2×4 wall Continuous insulation with R-value ≥ 11.25 over 2×6 wall |

| 7 | Continuous insulation with R-value ≥ 10 over 2×4 wall Continuous insulation with R-value ≥ 15 over 2×6 wall |

| 8 | Continuous insulation with R-value ≥ 12.5 over 2x4 wall Continuous insulation with R-value ≥ 20 over 2x6 wall |

*Vented cladding includes vinyl, polypropylene, or horizontal aluminum siding, brick veneer with a minimum 1” airspace between the brick and weather-resistive barrier, rainscreen systems, or other approved claddings.

Vapor Retarders in Warm Climate Zones 1, 2, 3, and 4

The IRC does not require or prohibit the use of vapor retarders in climate zones 1, 2, 3, and 4 (except Marine 4). NAIMA recommends using either a Class II or III vapor retarder in these warmer climate zones and avoiding the use of Class I (very low perm) vapor retarders. Kraft-faced batts can be installed in all climate zones.

In the warmer climate zones, installing vapor retarder with a very low perm rating on the interior of a wall assembly can lead to moisture problems. Even vinyl wall paper, which has a low perm rating, can induce moisture problems in warm, humid climates where hot, moist conditions tend to drive moisture into the wall from the outside of the building.

In very warm, humid climates, if a vapor retarder is used, NAIMA recommends installing it to the exterior side of the wall.

Vapor Retarders in Cold Climate Zones (5, 6, 7, 8 and Marine 4):

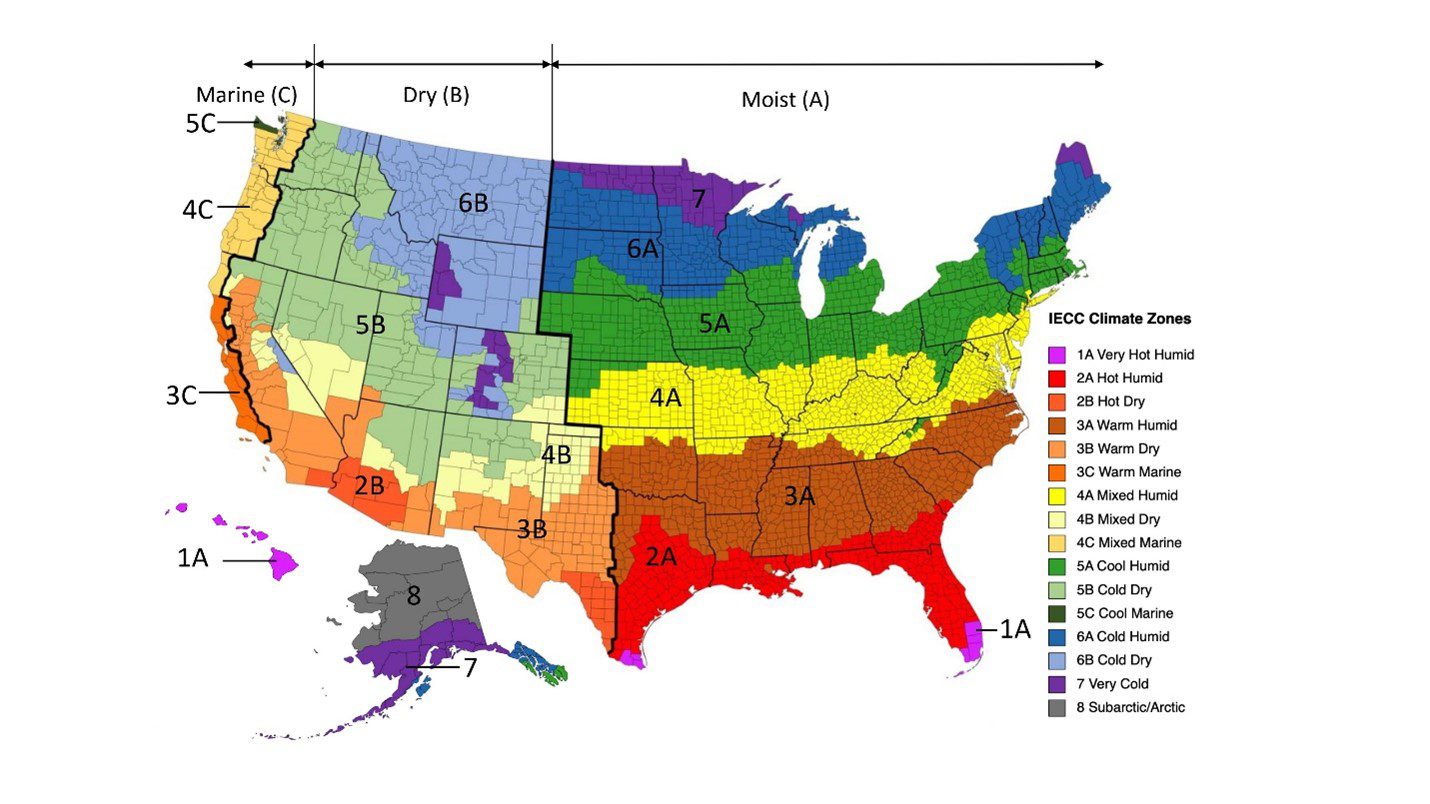

The IRC requires either a Class I or II vapor retarder on the interior side of frame walls in climate zones 5, 6, 7, 8 and Marine 4 (see climate zone map). A vapor retarder is not required for basement walls or on any portion of the wall that is below ground or on walls made of materials that can’t be damaged by moisture or by freezing.

New to the 2021 IRC and 2021 IBC are prescriptive insulation allowances that will apply to insulation used to control moisture in order to permit the use of Class II responsive vapor retarders. Keep in mind that the insulation used to satisfy this option contributes to rather than supersedes the thermal envelope requirements of the energy code.

IECC/ASHRAE Climate Zone Map

Recommended vapor retarder requirements are based on the DOE developed climate zone map which divides the United States, by county, into eight temperature-oriented climate zones. The zones are further divided into three moisture categories designated A, B and C.